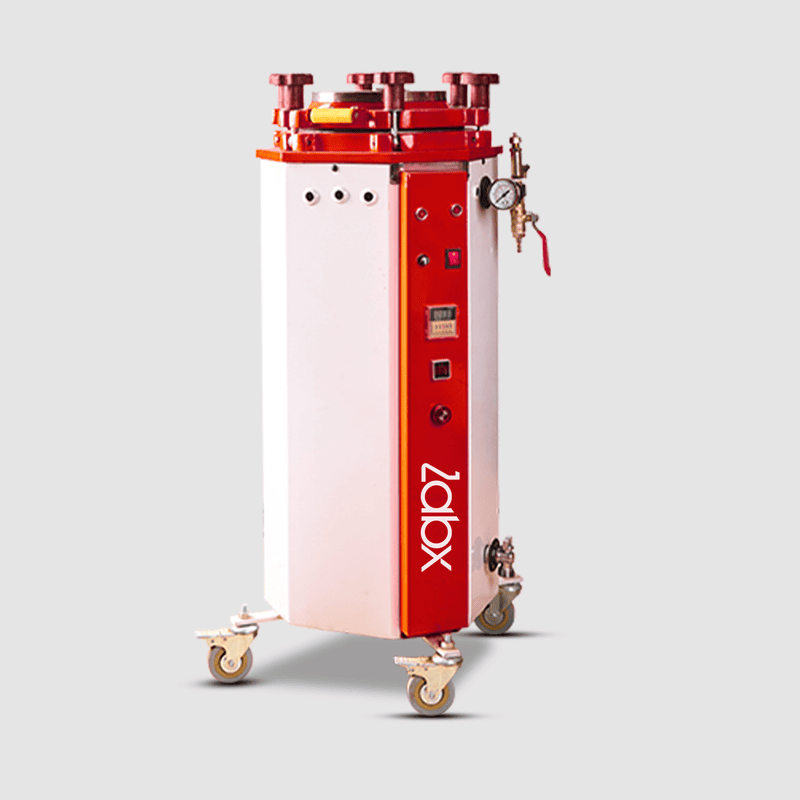

An autoclave is one of the most essential pieces of sterilization equipment in any medical, scientific, or industrial environment. Whether you operate a medical clinic, dental office, research laboratory, pharmaceutical factory, or cosmetics facility, a reliable autoclave ensures that every tool, instrument, or material is 100% sterile, safe, and contamination-free. At LabXTech, we provide high-performance autoclaves designed with advanced technology, durable materials, and precise temperature control to guarantee consistent and effective sterilization results.

Sterilization is a critical step in any workflow involving reusable instruments. An autoclave uses high-pressure saturated steam to eliminate bacteria, viruses, fungi, and spores in a fast, efficient, and eco-friendly method. With rising global standards in hygiene and safety, investing in a premium autoclave is not just a requirement — it’s a long-term business decision that protects your clients, your staff, and your entire operation.

In this detailed guide, we explore everything you need to know about autoclaves, their benefits, main features, usage, and why choosing a high-quality model from LabXTech can significantly improve your sterilization workflow.

What Is an Autoclave?

An autoclave is a steam sterilization device that uses high pressure and high temperature to kill all forms of microbial life. The standard sterilization cycle typically reaches 121–134°C under a pressure of 1.5–2.5 bars, depending on the model and material being sterilized.

Autoclaves are widely used in:

-

Medical centers and hospitals

-

Dental clinics

-

Scientific research laboratories

-

Industrial quality-control labs

-

Universities and educational facilities

-

Veterinary clinics

-

Pharmaceutical and cosmetic production lines

This makes the autoclave one of the most versatile and indispensable devices in modern sterilization.

How Does an Autoclave Work?

The sterilization process is based on a simple scientific principle: high-pressure steam can penetrate deeply into instruments and destroy microorganisms at a cellular level.

A standard autoclave cycle involves:

-

Heating – The autoclave generates steam and builds pressure inside the chamber.

-

Sterilization (Holding Time) – The temperature remains stable at 121–134°C for a set amount of time.

-

Exhaust Phase – Steam is released and pressure drops safely.

-

Drying Phase – Hot air dries the instruments to prevent corrosion and maintain sterility.

The result is a full sterilization cycle that ensures everything inside the chamber is safe to reuse.

Why Your Laboratory or Clinic Needs an Autoclave

1. Guaranteed Sterilization

An autoclave provides complete microbial elimination, ensuring your tools are safe for patient contact and laboratory use. This is essential for complying with international hygiene standards and preventing infections.

2. Cost-Effective Long-Term Investment

Instead of continuously purchasing disposable tools, an autoclave allows you to reuse high-quality instruments, lowering your operational costs.

3. Enhances safety and professionalism

Reliable sterilization boosts the reputation of your business — whether medical, scientific, or industrial — as clients trust environments that prioritize safety.

4. Faster Workflow

Modern autoclaves offer short cycles and rapid heating, allowing you to sterilize multiple sets of tools throughout the day without downtime.

5. Required by regulatory authorities

Most industries require autoclaves for certification, inspections, and legal compliance. Having a high-quality unit keeps your business aligned with regulations.

Key Features of Our Autoclave (LabXTech)

When choosing an autoclave, quality and durability matter. LabXTech provides sterilization equipment designed to deliver stable performance in demanding environments.

✔ High-Pressure Steam Technology

Ensures deep sterilization for all types of instruments, including metal tools, labware, glass, textiles, and selected plastic materials.

✔ Stainless Steel Chamber

Made from medical-grade stainless steel, resistant to heat, corrosion, and long-term wear.

✔ Digital Control Panel

User-friendly interface for adjusting temperature, pressure, cycles, and drying settings.

✔ Automatic Safety Systems

Includes pressure safety valves, temperature sensors, overheating protection, and automatic shut-off functions.

✔ Fast Drying System

Ensures instruments come out completely dry, preventing corrosion and contamination.

✔ Multiple Sterilization Programs

Designed for different materials and load types, such as solid tools, porous loads, liquids, and wrapped instruments.

✔ Energy-Efficient Design

Built to reduce electricity consumption while maintaining fast and effective performance.

Types of Autoclaves Available

Depending on your laboratory or clinic needs, autoclaves come in different types. The most common include:

1. Vertical Autoclave

Ideal for labs with limited space. Efficient for sterilizing glassware, instruments, and culture media.

2. Horizontal Autoclave

Large-capacity units used in hospitals, universities, and manufacturing plants.

3. Class B Autoclave (Dental & Medical)

Designed for clinics requiring rapid and intensive sterilization cycles for wrapped and hollow instruments.

4. Portable / Small Autoclave

Compact and suitable for small clinics or mobile operations.

LabXTech provides all these options with reliable performance and high-quality materials.

Applications of Autoclaves

Autoclaves play a major role in multiple professional environments:

-

Hospitals & Clinics – Sterilizing surgical tools, dental instruments, and medical equipment.

-

Laboratories – Sterilizing culture media, glassware, and biological waste.

-

Pharmaceutical Production – Ensuring sterile production of drugs and laboratory testing.

-

Cosmetics Factories – Sterilizing bottles, jars, and tools before filling.

-

Veterinary Clinics – Sterilizing surgical instruments and grooming tools.

-

Tattoo & Beauty Studios – Ensuring client safety and tool sterilization.

Why Choose LabXTech Autoclaves?

1. High Quality and Durability

Our autoclaves are built to withstand intensive daily use.

2. Professional Customer Support

We provide consultation, installation guidance, and after-sales support.

3. Competitive Pricing

We offer top-tier sterilization equipment at affordable prices, making it ideal for startups and established facilities.

4. Suitable for the Egyptian Market

Our autoclaves are optimized for use in Egypt, including voltage compatibility, spare parts availability, and local support.

5. Trusted by Professionals

Used by hundreds of laboratories, medical centers, and factories across the region.

Maintenance Tips for Long Autoclave Lifespan

To keep your autoclave performing efficiently, follow these care tips:

-

Use distilled water to prevent mineral buildup.

-

Clean the chamber regularly.

-

Check gaskets and seals for wear.

-

Run a cleaning cycle weekly.

-

Schedule periodic maintenance with a certified technician.

These steps help extend the lifetime of your autoclave and prevent unexpected downtime.

Conclusion

An autoclave is essential for ensuring safe, sterile, and contamination-free tools in any medical, scientific, or industrial operation. With a high-quality autoclave from LabXTech, you get efficient sterilization, reliable performance, and a long-lasting investment that supports your professional workflow.

If you’re looking for a durable, high-performance, and competitively priced autoclave, explore our product here:

Autoclave – LabXTech

https://labxtech-eg.com/products/autoclave/